Constant Or Controlled Filling Fluid Coupling

1. The fluid coupling has the function of shock mitigation and torsional vibration isolation.

2. The Hydro-Coupling can improve the starting capacity of the engine, so that it can start with load or no load.

3. The fluid coupling has strong adaptability to the environment and can work in cold, wet, dust and explosion-proof environments.

Our company can customize different types of hydraulic couplings, please contact us if necessary!

- Information

- Video

Product Description:

The constant or controlled filling fluid coupling increases the braking function, the motor shaft is connected with the input coupling of the coupling, the centrality is nice and the operation is stable.In addition, the constant or controlled filling fluid coupling increases the rear auxiliary chamber, prolongs the oil filling time of the rear auxiliary chamber to the working chamber, and this structure can reduce the starting torque and extend the starting time.Last but not least, this type of coupling is easy to install, align and can be removed without moving the machine.

Function:

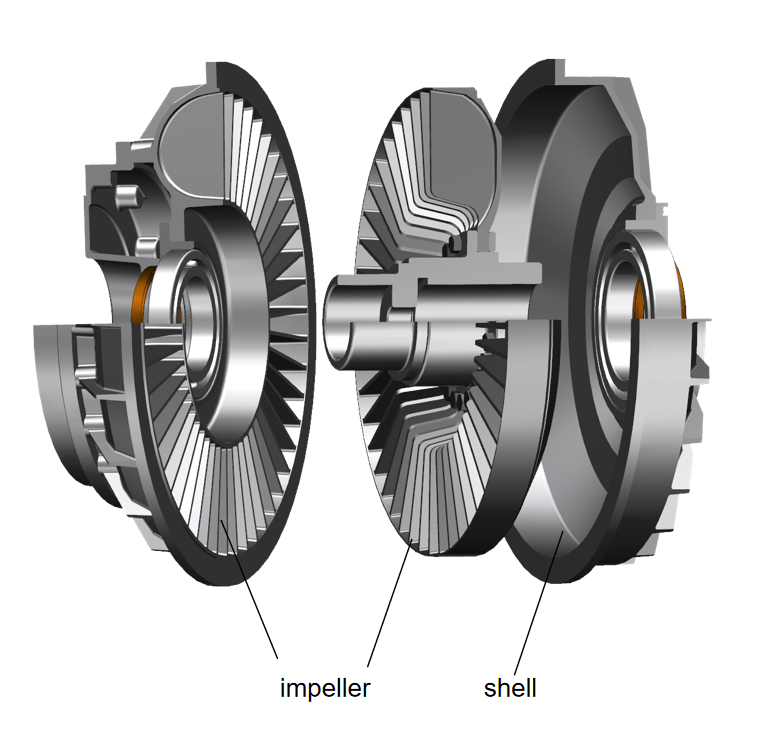

The Constant Or Controlled Filling Fluid Coupling is a hydraulic coupling developed according to Feddinger's principle.The main components of the coupling consist of two impellers - the pump wheel and the turbine - and a closed housing.The two impellers are placed corresponding to each other.The hydrocoupling can achieve wear-free power transmission, and there is no mechanical contact between the components that transmit power.The amount of working fluid in the coupling is constant.The mechanical energy generated by the drive motor is converted into the flow energy of the working fluid in the pump wheel connected to it.The turbine then converts the flow energy into mechanical energy.

Product Detaled:

The advantages of the constant or controlled filling fluid coupling:

1. The coupling flexible transmission can automatically adapt to the function.

2. The overload protection function of the coupling protects the motor and the working machine from damage when the external load is overloaded, and the overload coefficient is 2--2.5.

3. The hydrocoupling coordinate the sequential start of multiple engines, load balancing and smooth running.

4. The hydrocoupling has the function of making the working machine start slowly and delay, and can start the large inertia machinery smoothly.

5. The fluid coupling can use cheap cage motors instead of expensive winding motors.

6. The hydrocoupling has no pollution to the environment.

7. The hydrocoupling has the function of expanding the stable operation range of the engine.

8. The hydrocoupling has a power-saving effect, which can reduce the starting current and duration of the motor and reduce the impact on the grid.

9. The coupling has low failure rate, long service life, and easy use, repair and maintenance.