- Home

- >

- Products

- >

- Solid Coupling

- >

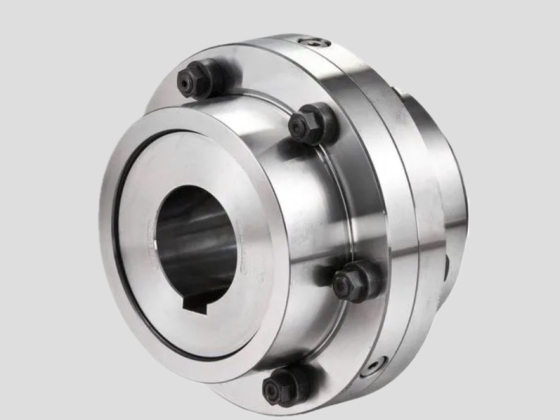

Solid Coupling

1.Whether it is machines running on production lines or equipment in different industries, rigid couplings play a vital role in power transmission.

2.Whether it is a heavy-duty conveyor belt system or a light-duty conveyor mechanism, rigid couplings play a vital role in connecting transmission components such as motors and conveyor wheels.

If you need such products, please contact us. Our shop offers a wide range of options to meet your specific needs.

- Information

Another name for solid coupling:

1.sleeve coupling

2.flange coupling

3.ribbed coupling

product description:

Sleeve coupling is a torsionally rigid coupling that has no rotational clearance even when it is loaded. Even when there is a load due to deviation, the sleeve coupling still transmits torque rigidly.

Product Advantages:

1. Stability and accuracy: flange coupling provide a high level of torque transmission stability and accuracy. They maintain shaft alignment, ensuring there is minimal angular or parallel misalignment between connected shafts.

2. High torque transmission: flange coupling are designed to handle high torque loads. This makes them suitable for heavy-duty applications that require a safe, strong connection to transfer large amounts of power between shafts.

3. No Backlash: Unlike other types of couplings,flange coupling have virtually zero backlash.

4. Maintenance-free: Because the flange coupling has a simple and strong structure, it basically requires no maintenance.

5. Suitable for high-speed applications: ribbed coupling are often used in high-speed applications, such as machinery or rotating equipment, where precise synchronization and high rotational speeds are critical.

6. Reduces Vibration: ribbed coupling help minimize vibrations due to their sturdy construction and elimination of any misalignment.

7. Simple design and installation: ribbed coupling design is relatively simple and easy to install.

Product application occasions:

1. Transmission devices:sleeve coupling are commonly used in various mechanical transmission devices, such as machinery, water pumps, fans and compressors.

2. Industrial equipment and machinery: In various types of industrial equipment,sleeve coupling are widely used to meet the needs of mechanical connection, rotation transmission and torque transmission.

3. Agriculture and agricultural machinery and equipment: Agricultural machinery and equipment in the agricultural industry, such as tractors, harvesters and planters, usually require sleeve coupling to connect driving components, transmission shafts and various working mechanisms.

4. Papermaking machinery: sleeve coupling play a key role in papermaking machinery and are used to connect various rollers, conveyor belts and cutting devices to ensure precise rotation transmission and coordinated work.

5. Conveying equipment: Whether it is a heavy-duty conveyor belt system or a light-duty conveying mechanism, sleeve coupling play an important role in these equipments and are used to connect transmission components such as motors and transmission wheels.