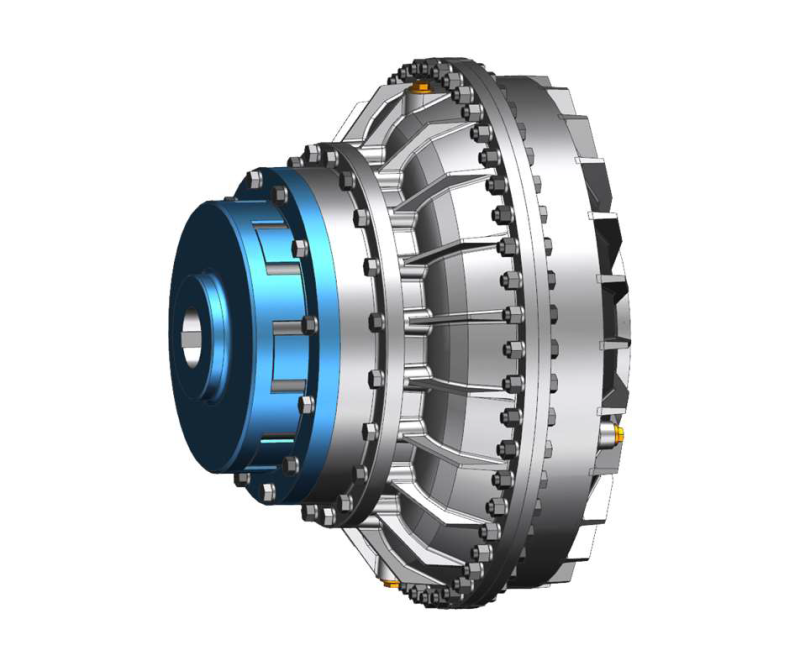

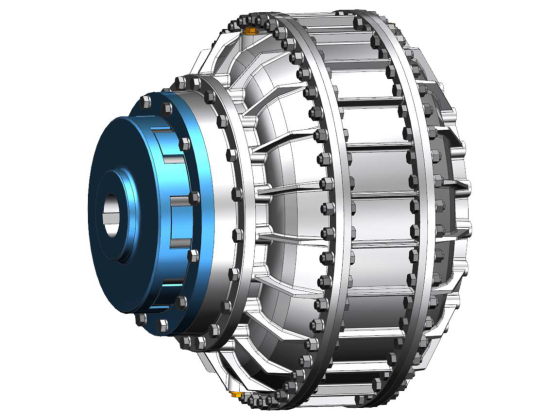

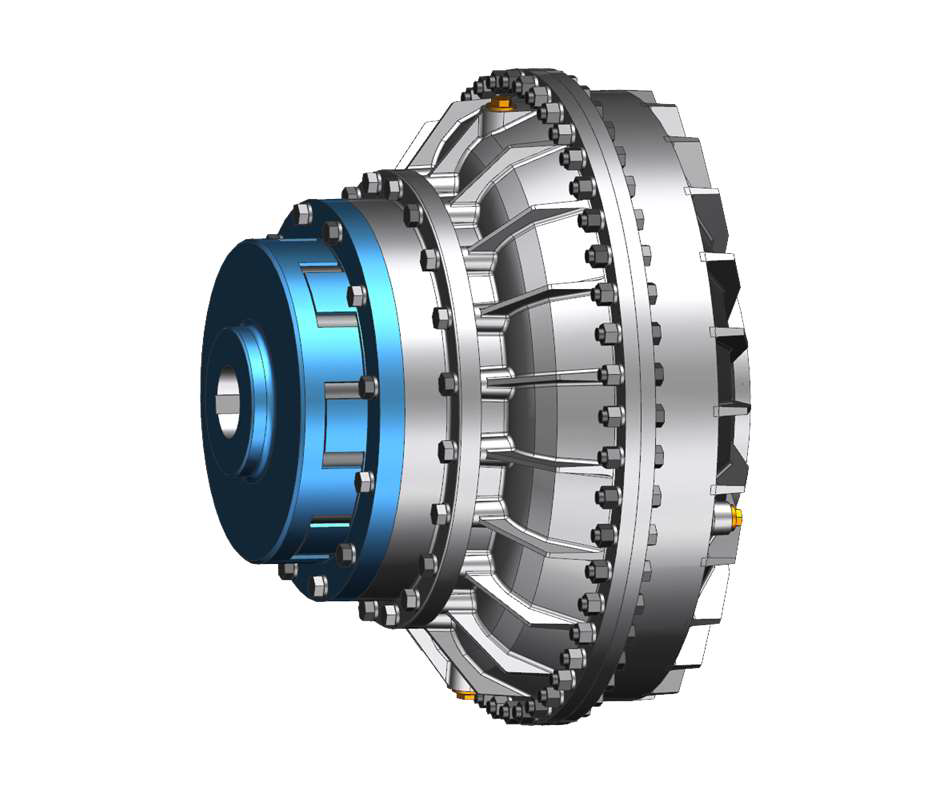

Basic Hydrodynamic coupling

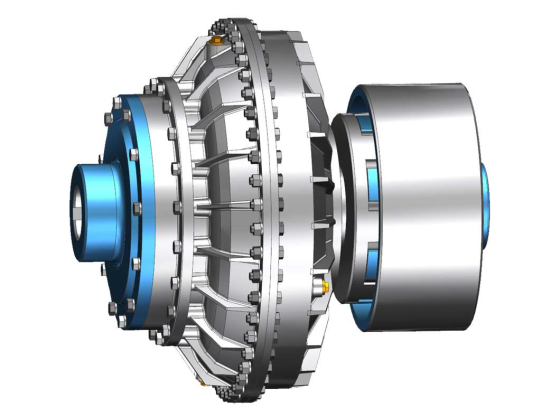

1. The hydrodynamic coupling can effectively buffer and absorb impact loads and reduce mechanical wear.

2. The hydrodynamic coupling can maintain high transmission efficiency and reduce energy loss under various working conditions.

3. The hydraulic coupling provides a variety of models and specifications to meet different industrial needs

4. The hydraulic coupling can adapt to various load changes and operating conditions. Whether it is high temperature, high humidity or dusty environment, its performance can remain stable.

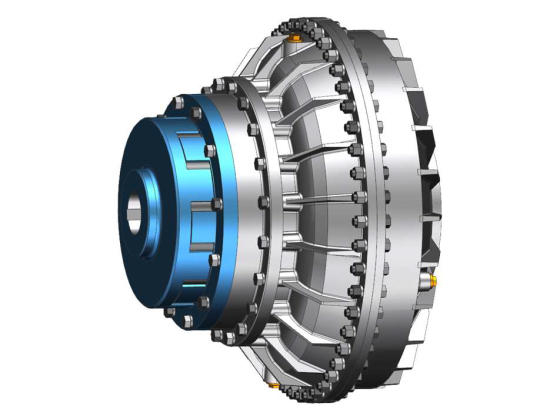

Brand: Merisen

Product origin: GERMANY

Suppky capacity: 2500/YERA

- Information

Product advantages:

1. The fluid coupling extend the service life of transmission systems and mechanical components by reducing friction and impact.

2. The fluid coupling optimize energy transfer efficiency, reduce energy consumption, and meet modern energy-saving and environmental protection requirements.

3. The fluid coupling have a relatively simple structure, are easy to maintain and overhaul, and reduce operating costs.

4. The fluid coupling can adjust the output torque according to demand to adapt to different working conditions.

Working principle:

The hydro coupling transmits power through liquid, and its basic structure consists of a pump wheel, a turbine and a casing. The power is transferred to the turbine by the rotation of the pump wheel, so that the liquid flows, and the kinetic energy of the liquid is transferred to the turbine, realizing the speed conversion and power transmission. In normal operation, a fluid connection is formed between the pump wheel and the turbine through the liquid, realizing contactless transmission. When the load is too large, the pressure of the liquid flow will increase, causing the turbine speed to drop, thus realizing the protection mechanism.

Application scenarios:

the hydro coupling are widely used in multiple industries and scenarios. In heavy industry, hydraulic couplings are often used for power transmission in mining, metallurgy and chemical equipment. In transportation equipment, such as conveyor belts and cranes, hydraulic couplings can achieve smooth load regulation and avoid severe vibration of equipment during operation. In agricultural machinery, such as tractors and combine harvesters, hydraulic couplings also play an important role in the field of construction equipment and are often used in equipment such as concrete mixers and excavators.

Our services:

We are a professional manufacturer of hydraulic machinery and equipment, and we can provide customers with personalized customized services. Each customer's needs are unique, so we will work closely with you to deeply understand your specific requirements. From product design to material selection, we can adjust according to your needs to ensure that each product can perfectly match your application scenario. Whether it is large industrial equipment or small machinery, we can provide you with the right size and specifications. In addition, if you need special functions, such as improving transmission efficiency or reducing noise, our team will also optimize the design for you.

At the same time, we also provide comprehensive after-sales service. If you have any needs or questions, please feel free to contact us.