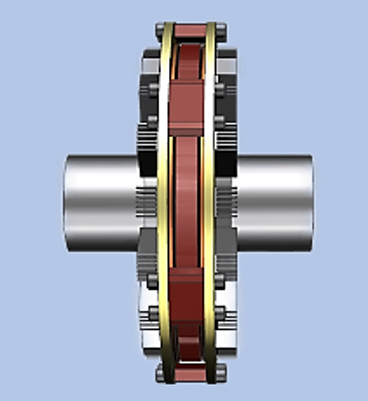

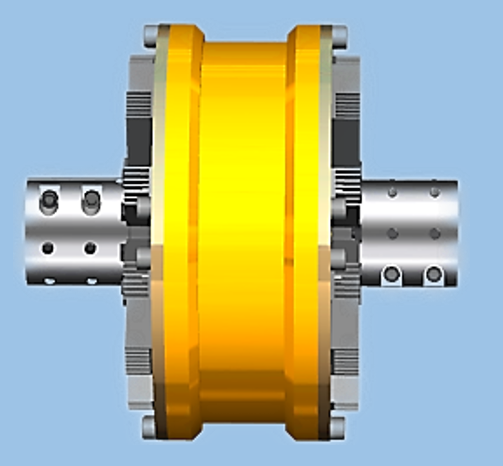

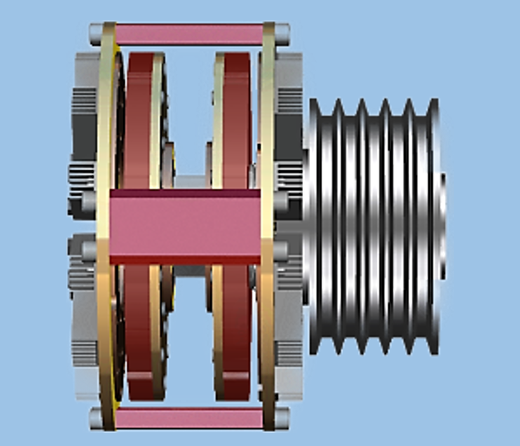

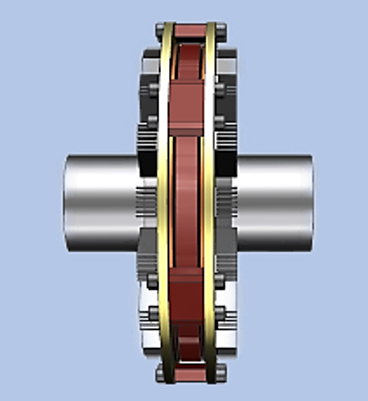

Basic Permanent Magnetic coupling

1. The basic permanent magnetic coupling uses permanent magnet materials to achieve contactless transmission, which improves energy transmission efficiency and reduces energy loss.

2. The basic permanent magnetic coupling has a compact design, takes up little space, and is suitable for the installation needs of various equipment.

3. The basic permanent magnetic coupling is made of high-quality materials, which has good wear resistance and corrosion resistance and extends its service life.

4. The basic permanent magnetic coupling has no mechanical contact and the noise during operation is significantly reduced.

5. The basic permanent magnetic coupling can adapt to stable operation in harsh working environments.

- Information

- Download

Product Advantages:

1. The permanent magnetic coupling through permanent magnetic force, avoiding the energy loss caused by friction in traditional couplers.

2. The permanent magnetic coupling has no wearing parts, reducing maintenance frequency and cost. .

3. The permanent magnetic coupling adapts to different speed requirements and can achieve precise control.

4. The permanent magnetic coupling avoids liquid or mechanical connection failures and ensures safe operation.

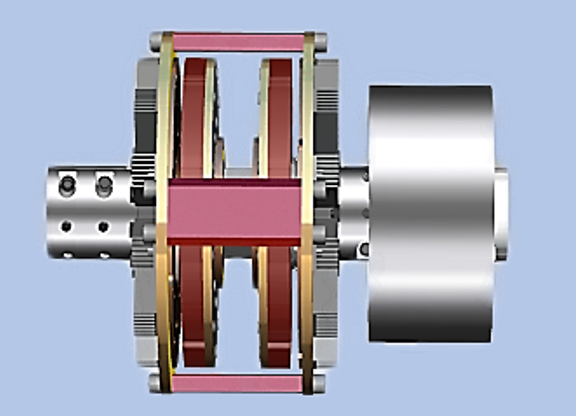

Working Principle:

The working principle of the basic permanent magnetic coupling is to use the magnetic field interaction between permanent magnets to achieve power transmission. The coupler consists of two rotors at the input and output ends. The input rotor is driven by the motor and the output rotor is connected to the load. When the input rotor rotates, its magnetic field is transmitted to the output rotor through the permanent magnet, causing it to rotate. Since there is no direct contact between the two, the friction and wear of the traditional coupler are avoided, achieving efficient and smooth power transmission.

Application scenarios:

1. The magnetic coupling is widely used in water pumps, chemical pumps and other occasions that require stable flow and high efficiency.

2. The magnetic coupling can be used in equipment such as fans and air-conditioning compressors to reduce noise and improve efficiency.

3. The magnetic coupling can be used in precision instruments in the medical industry to ensure the safety and reliability of the equipment.

4. The magnetic coupling is suitable for various automation equipment and production lines to improve production efficiency and safety.

5. The magnetic coupling can be used in industrial robots and service robots to improve motion accuracy and control capabilities.

Our services:

We are a professional manufacturer of couplings and can provide customers with personalized customization services. Each customer's needs are unique, so we will work closely with you to deeply understand your specific requirements. From product design to material selection, we can adjust according to your needs to ensure that each product can perfectly match your application scenario. Whether it is large industrial equipment or small machinery, we can provide you with the right size and specifications. In addition, if you need special functions, such as improving transmission efficiency or reducing noise, our team will also optimize the design for you.

At the same time, we also provide comprehensive after-sales service. If you have any needs or questions, please feel free to contact us.