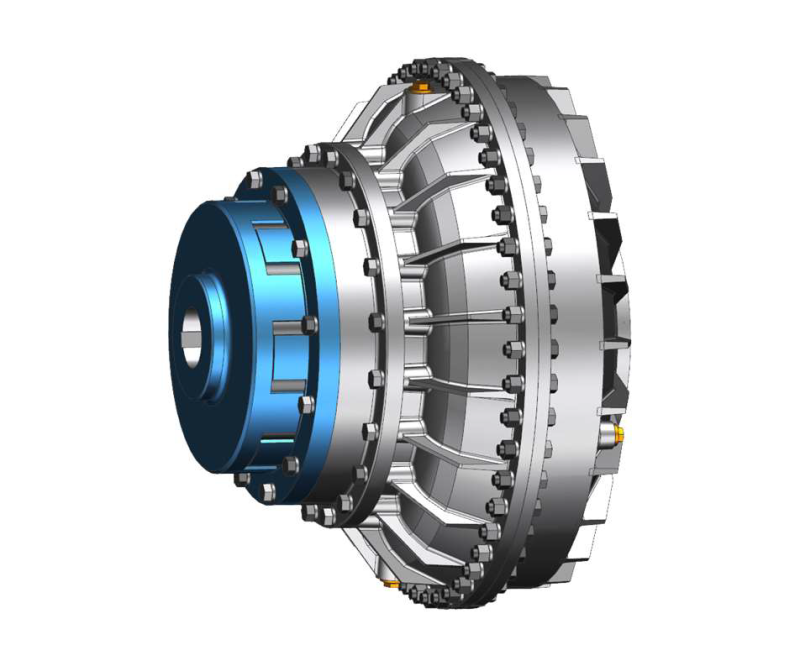

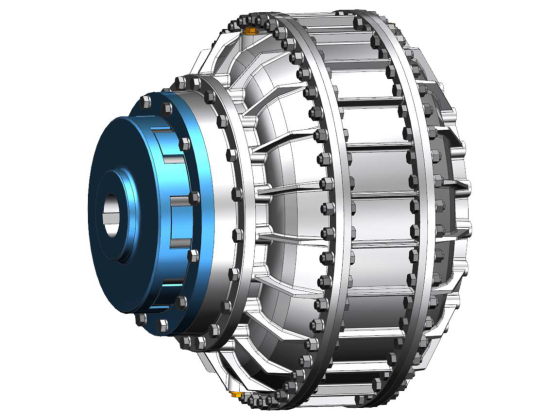

Hydrodynamic coupling with enlarged delayed filling chamber

1. The hydrodynamic coupling with enlarged delayed filling chamber adopts a larger delayed filling chamber design to effectively improve efficiency.

2. The hydrodynamic coupling with enlarged delayed filling chamber effectively absorbs shock and vibration, protects equipment and extends service life.

3. The Hydrodynamic coupling with Enlarged DelayChamber can operate stably in high and low temperature environments and adapt to a variety of working conditions.

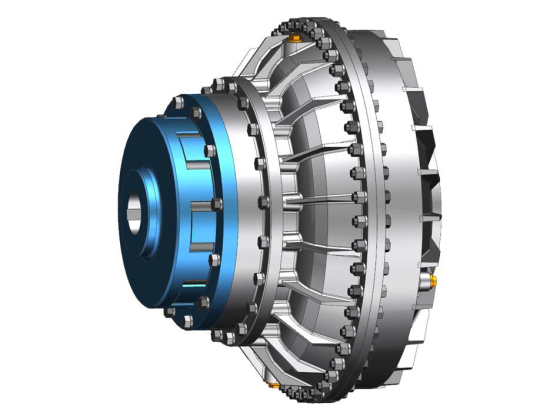

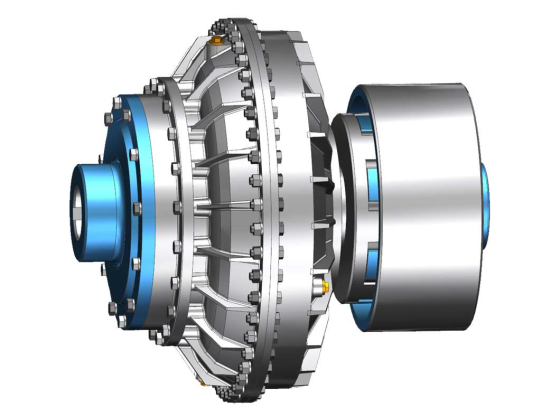

4. The hydro coupling structural design facilitates daily maintenance and inspection, reducing maintenance costs.

5. The hydro coupling with enlarged delayed filling chamber provides a variety of specifications and material options according to customer needs to meet different application scenarios.

Beand: Merisen

Product origin: GERMANY

Supply capacity: 2000SETS/YERA

- Information

- Video

Product advantages:

1. The fluid coupling has little impact on the environment and meets the requirements of modern green production.

2. The fluid coupling can also stably transmit under high load conditions and adapt to heavy load conditions.

3. The Hydraulic coupling with Enlarged DelayChamber can effectively prevent overload and overheating, ensuring the safe operation of the equipment.

4. The Hydraulic coupling with Enlarged DelayChamber can be widely used in various industrial equipment and has strong compatibility

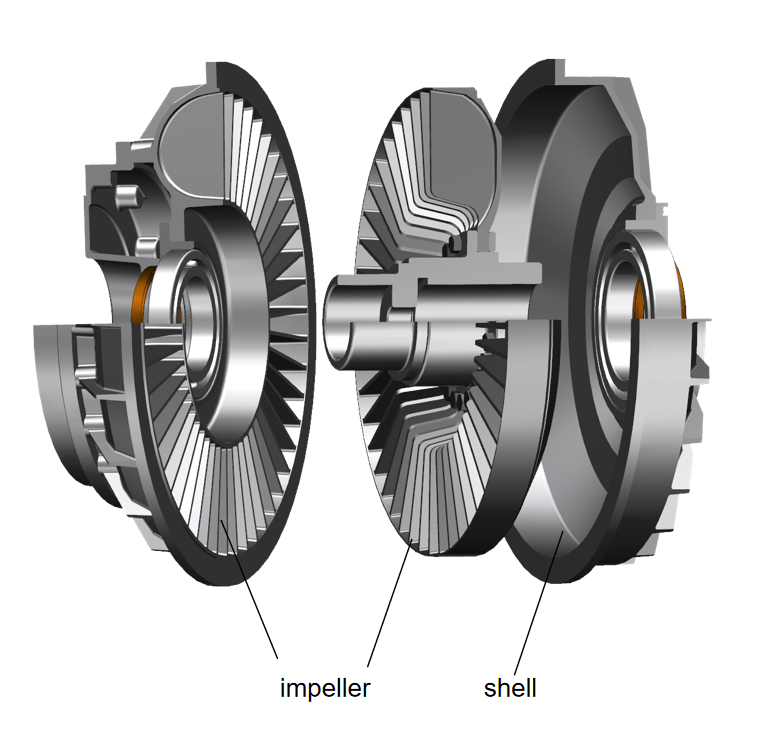

Working Principle:

The working principle of the hydraulic coupling with enlarged delayed filling chamber with enlarged delayed filling chamber is based on fluid dynamics. It is filled with liquid. When the input shaft rotates, the liquid flows in the chamber, thereby driving the output shaft. The "delayed filling chamber" of this design can effectively adjust the filling speed of the fluid, achieve slow torque transmission, and reduce instantaneous load impact. At the same time, the flow characteristics of the liquid make the coupling have a good shock absorption effect, thereby improving the overall stability of the system.

Product Detaled:

Application scenarios:

Hydraulic coupling with Enlarged Delayed Chamber are widely used in various mechanical equipment to help improve production efficiency and safety. They are suitable for equipment in the mining, construction and heavy industry industries. They can also be used in conveyors and hoists to effectively buffer and reduce transmission vibrations. They are suitable for fluid transportation and gas processing to ensure stable operating performance. They are used in agricultural equipment to adapt to various working environments and improve operating efficiency. In generator sets, they provide reliable power transmission and safety protection.

Our services:

We are a professional manufacturer of hydraulic machinery and equipment, and we can provide customers with personalized customized services. Each customer's needs are unique, so we will work closely with you to deeply understand your specific requirements. From product design to material selection, we can adjust according to your needs to ensure that each product can perfectly match your application scenario. Whether it is large industrial equipment or small machinery, we can provide you with the right size and specifications. In addition, if you need special functions, such as improving transmission efficiency or reducing noise, our team will also optimize the design for you.

At the same time, we also provide comprehensive after-sales service. If you have any needs or questions, please feel free to contact us.