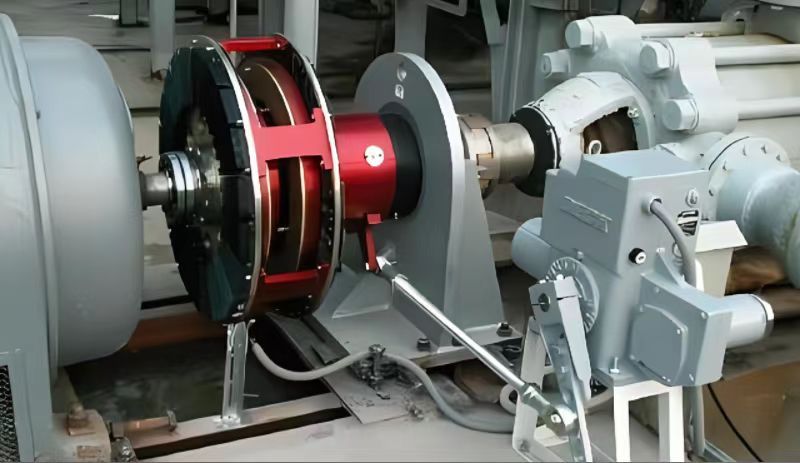

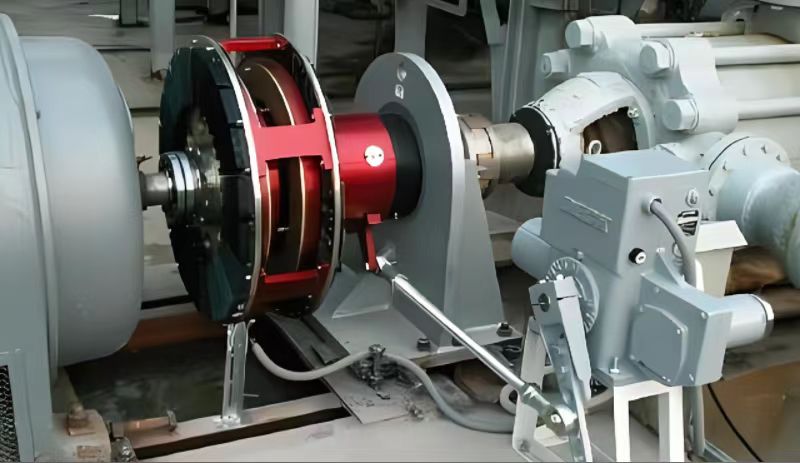

Speed Regulating Controller Magnetic Coupling

1.They provide efficient speed regulation capabilities and play a vital role in ensuring optimal performance and productivity in various processes.

2.By utilizing the magnetic field between the driving and driven elements, permanent magnet coupling eliminate the need for physical contact, thereby reducing friction, wear and maintenance requirements.

3.By adjusting the strength of the magnetic field, the magnetic speed regulator can effectively control the speed of the driven components, preventing damage or inefficiency caused by excessive speed.

If you need such products, please contact us. Our shop offers a wide range of options to meet your specific needs.

- Information

Another name for speed regulating controller magnetic coupling:

1.magnetic governor

2.permanent magnet transmission

3.permanent magnet coupling

Product Description:

The magnetic governor use magnets to transmit torque between two rotating shafts without mechanical contact between them. It consists of an outer rotor with a magnetic field and an inner rotor that responds to the magnetic field and transmits torque. By varying the strength of the magnetic field, the amount of torque transferred between the shafts can be controlled, allowing speed regulation.

Product Advantages:

1.Precise Speed Control: permanent magnet coupling provides accurate and precise speed control, enabling the adjustment of rotational speed based on the specific requirements of the application.

2.Energy Efficiency: By allowing for variable speed operation and reducing energy loss, permanent magnet coupling can significantly contribute to energy efficiency in various applications.

3.Smooth Torque Transfer: permanent magnet coupling enables a smooth and non-contact transfer of torque between shafts, leading to reduced wear and tear, as well as lower maintenance requirements.

4.Overload Protection: permanent magnet coupling can help protect equipment from damage by limiting torque during overload conditions.

5.No Mechanical Friction: Since there is no direct mechanical contact between the inner and outer rotors, the permanent magnet transmission eliminates issues related to mechanical wear and friction loss.

6.Maintenance Friendly: With fewer moving parts and reduced wear, they generally require less maintenance compared to traditional mechanical couplings.

7.No Lubrication Requirements: As there are no gears or other mechanical parts rubbing against each other, there is often no need for lubrication, reducing operational costs and environmental impact.

8.Reduced Vibration and Noise:Given the absence of physical contact between components,permanent magnet transmission can contribute to smoother and quieter operation.

Product application occasions:

1. Wind power generation: the magnetic governor are often used in wind turbines to connect the fan blade shaft and the generator so that the rotation speed of the fan blades can be adjusted as the wind speed changes.

2. Mining: In mine ventilation systems: the magnetic governor can be used to connect fans and motors to adjust the ventilation air volume and maintain the air quality and temperature in the mine.

3. Manufacturing industry: the magnetic governor can be used in conveyor belt systems, fans, pumps and other equipment to adjust the speed and torque of the equipment according to production needs and operating conditions.

4. Water pumps and compressors: In water treatment plants, sewage treatment plants and other liquid and gas treatment equipment, the magnetic governor can be used to adjust the operating speed of pumps and compressors to meet different process requirements.

5. Electric power industry: the magnetic governor is also widely used in auxiliary equipment of thermal power plants and nuclear power plants, such as coal feeders, ash feeders, blowers and dust removal equipment.