Pin Gear Coupling: Structure, Features, and Applications

2025-03-27 08:38Overview

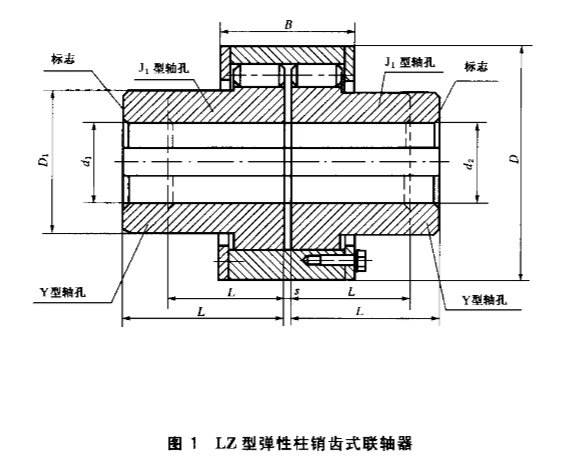

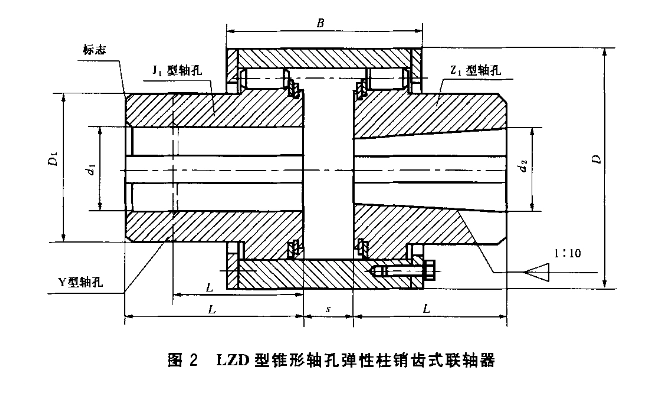

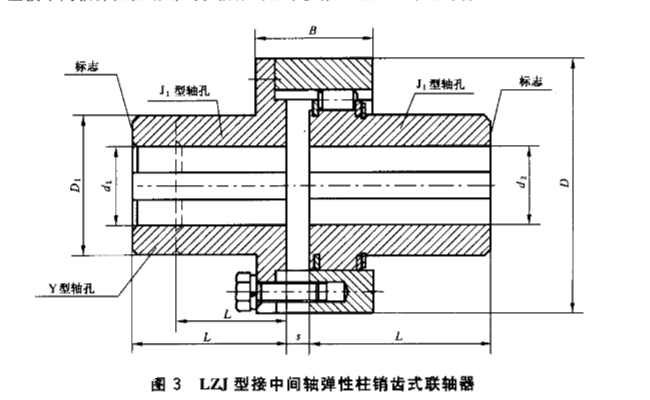

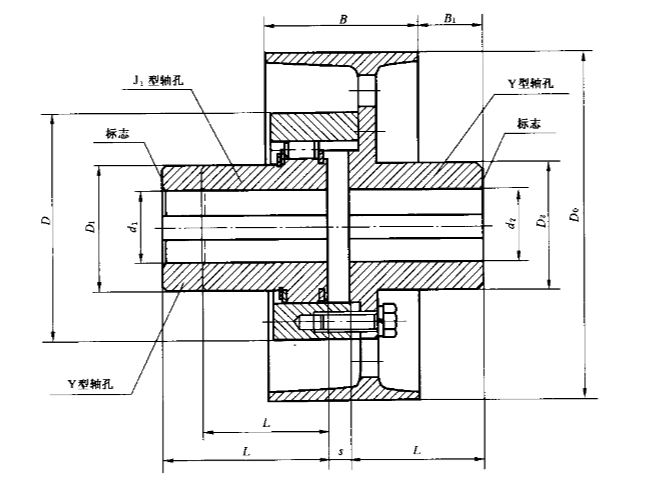

The Pin Gear Coupling utilizes non-metallic pins installed between the semi-couplings and the outer ring’s inner surface. These pins transmit torque to connect the two semi-couplings. It offers excellent compensation for axial, radial, and angular misalignments, along with advantages like vibration damping, simple structure, noiseless operation, and maintenance-free lubrication. Its cost-effectiveness, adaptability, and ease of installation make it widely applicable across industries.

Structure and Classification

The coupling consists of two semi-couplings with semicircular grooves on their outer edges and the inner surface of the outer ring, forming pin holes for nylon pins. Torque is transmitted from the driving shaft to the outer ring and then to the driven shaft. Shaft holes and keyways comply with the GB/T3852-1977 standard (Coupling Shaft Holes and Connection Types and Dimensions) and can integrate with locking devices.

Four main types include:

LZ Type Pin Gear Coupling

LZD Type Tapered Shaft Hole Pin Gear Coupling

LZJ Type Intermediate Shaft Pin Gear Coupling

LZZ Type Brake Wheel Pin Gear Coupling

Key Features

High Torque Transmission: Compact design with smaller radial dimensions compared to gear couplings, suitable for replacing traditional gear couplings.

Simplified Construction: Fewer components, no need for specialized gear machining, and reduced manufacturing complexity.

Easy Maintenance: Nylon pins can be replaced by removing the retaining plate, minimizing downtime.

Self-Lubricating: Nylon pins eliminate lubrication requirements, enhancing cleanliness in operational environments.

Limitations: Limited vibration damping and higher noise levels, making it unsuitable for noise-sensitive applications.

Applications

The Pin Gear Coupling is ideal for medium-to-high power transmission systems requiring moderate misalignment compensation. Its self-lubricating nylon pins reduce maintenance and environmental contamination. However, due to its reliance on shear stress for elasticity, it is less reliable for high-precision or high-speed scenarios. A standout advantage is single-time alignment installation, which saves time and effort, especially in challenging alignment conditions.

Comparison with Other Couplings

Combining the benefits of elastic couplings (e.g., plum-type couplings), it avoids complex disassembly for pin replacement. Unlike double-flange plum-type couplings, it maintains simplicity while reducing weight and inertia, broadening its applicability.