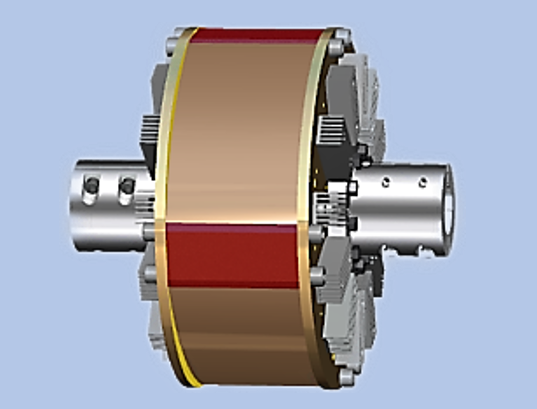

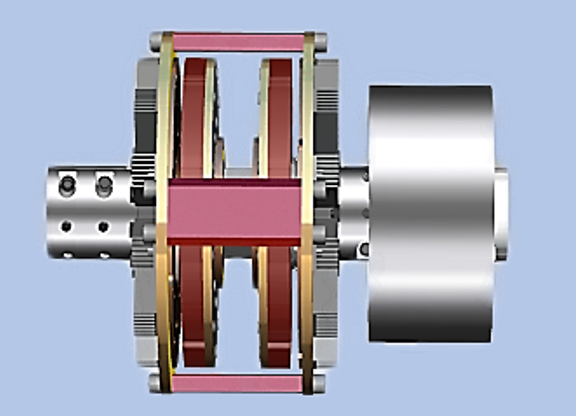

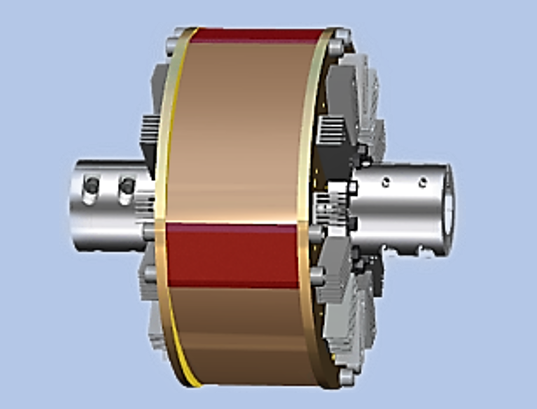

Semi Enclosed Torque Limiting Permanent Magnetic coupling

1. The semi enclosed torque limiting permanent magnetic coupling uses advanced permanent magnet materials to significantly reduce energy loss.

2. The semi enclosed torque limiting permanent magnetic coupling is suitable for a variety of space-restricted application scenarios.

3. The semi enclosed torque limiting permanent magnetic coupling with limited torque provides high torque transmission capability and is suitable for heavy-duty applications.

4. The semi enclosed torque limiting permanent magnetic coupling does not produce direct contact during transmission, effectively reducing wear.

5. The semi enclosed torque limiting permanent magnetic coupling has good dust-proof and waterproof performance.

- Information

- Download

Product Advantages:

1. The semi enclosed torque limiting magnetic coupling has no frictional contact, which reduces maintenance frequency and saves maintenance costs.

2. The semi enclosed torque limiting magnetic coupling has a smooth transmission process, no impact, and low noise.

3. The semi enclosed torque limiting magnetic coupling can work in various industrial environments.

4. The semi enclosed torque limiting magnetic coupling has no mechanical contact, which reduces safety hazards caused by equipment failure.

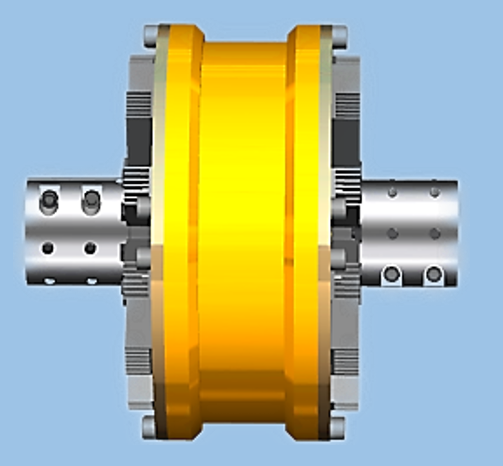

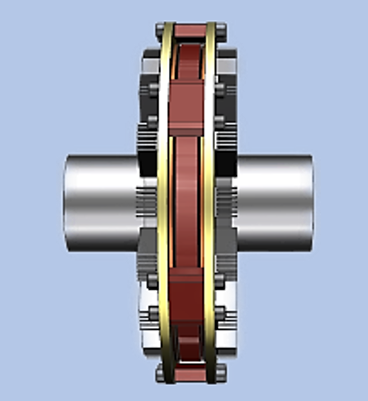

Working Principle:

The working principle of the magnetic coupling is based on the interaction of permanent magnetic forces. It consists of two main parts: the input part and the output part. The input part is driven by the drive motor, and the output part is connected to the load. The two are connected by permanent magnets to achieve contactless transmission. When the input part rotates, the magnetic field generated by the permanent magnet transmits force to the output part, thereby driving the load. When the load increases, the repulsive force of the permanent magnet will automatically adjust to ensure stable transmission without slipping, improving the overall transmission efficiency.

Application scenarios:

1. Chemical industry: During the chemical reaction process, it is necessary to prevent leakage and contamination of mixed substances. The contactless characteristics of permanent magnetic couplings are very suitable.

2. Food and pharmaceutical industries: The requirements for cleanliness and safety are extremely high. The semi-enclosed design can effectively prevent the entry of external impurities and ensure product quality.

3. Water treatment equipment: used for equipment such as pumps and mixers to ensure stable operation under high load conditions.

4. Oil and gas: Working in extreme environments, permanent magnetic couplings can provide reliable power transmission and reduce equipment wear.

Conclusion:

The Semi-enclosed torque-limited permanent magnetic couplings are widely used in various industrial fields due to their high efficiency, stability and safety. They are an indispensable component in modern automation equipment. They have shown superior performance in improving production efficiency and reducing maintenance costs, and are an important force in promoting industrial development.